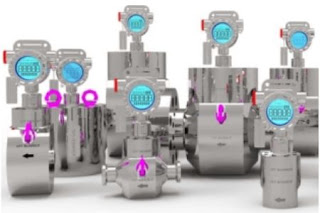

Litre Meter Pelton Wheel Series

Litre Meter pioneered the development of the Pelton wheel flowmeter: an accurate, effective and versatile design suitable for many different fluids including acids, chemicals, fuels, water and hot fats, at both high and low flow rates.

|

Litre Meter Pelton Wheel Series

|

Since 1986 Litre Meter has developed the VFF meter (literally, Viscous or Versatile Fluids Flowmeter) for low flow and high pressure applications for the offshore industry particularly for chemical injection. In 2011 we supplied the largest ever chemical injection flowmeter order for the Gulf of Mexico. Over 5,000 VFFs are now in operation on chemical injection.

Our portfolio for the UK now includes flowmeters of all kinds, including rotary meters, gas flowmeters, helical screw flowmeters and ultrasonic flowmeters to handle a wide range of viscosities, flow rates and pressures, aggressive liquids and hazardous or adverse environments. We have particular expertise in measuring low flow rates and flows at high pressure. Contact the flowmeter specialists.

Litre Meter hold ISO9001:2015 approval. We are members of the Institute of Manufacturing at Cambridge University, FPAL, Achilles, Institute of Measurement and Control and Northamptonshire Chamber of Commerce. Litre Meter is a member of the TASI Flow Division and won the Queen’s Award in 2016 for Enterprise in International Trade.

Pelton Wheel Series

Litre Meter have manufactured the LM GN, LM and MM range of Pelton Wheel turbine flowmeters since 1975.

Pelton wheel flowmeters are ideal for low viscosity liquids and low flows. The smaller flow ranges are handled by the LM series whilst for 1/2″ pipe sizes or 30 l/min and above the MM series is available. The original design, GN, has two hose connectors and a slightly limited range of sizes. Even so, flows from 0.01 to 28 l/min can be handled.

A wider selection is in the LMX range which has the LM003 at the low end (0.004 to 0.060 l/min/ 4-60 ml/min), some intermediate sizes and finishes up at the 280:1 LM220 – (from 0.1 to 28 l/min). The LMX has 1/2″ BSP or NPT male connections including a straight length to take care of odd flow profiles giving them an overall length of 180mm and a pressure rating of 100bar.

A 230bar version with an FPM seal rather than PTFE is optional. The KEM Kueppers VTC display can be specified for most Pelton meters here and provides a useful instrumentation function with a display, output, hazardous area and USB variation.

The MM pelton wheel design is notable in that it uses exactly the same rotor and ring assembly as the smaller LM range. It achieves this by being mounted in a bypass chamber across a custom orifice plate. The rotor movement is then proportional to the total flow through the meter. The threaded or piped sizes cover flow rates up to 220 l/min. Above that rate the design switches to a very compact wafer design. This gives a wide rangeability, typically 50:1 for the MM orifice/ by-pass meter. The MM12.5 size has 1/2″ connections just like the LMX.